Engraving on stainless steel.

The result is black image chemically fused into the metal

Method used is to coat the clean metal surface with Cermark ® a product of Ferro Corporation

Marks on stainless steel survived the following tests:

- Abrasion (scratch resistance)

- Salt water spray

- Lubricants

- Blow torch (available in spray cans)

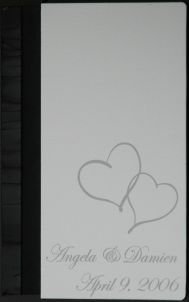

Fine detail can be achieved with excellent outdoor durability.

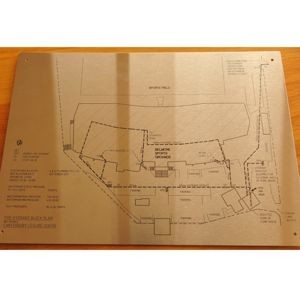

Detail plant illustations on stainless panels are commonly used where such information is required with long term life

eg Firefighting equipment, control panels of machinery in heavy duty environments, Air conditioning control panels

electrical cabinets. Underwater identification and valve tags.

example USB stainless steel device

example of plan for fire fighting system showing pipes, valves, and control points.